Belt Sanding Services at Microsheen

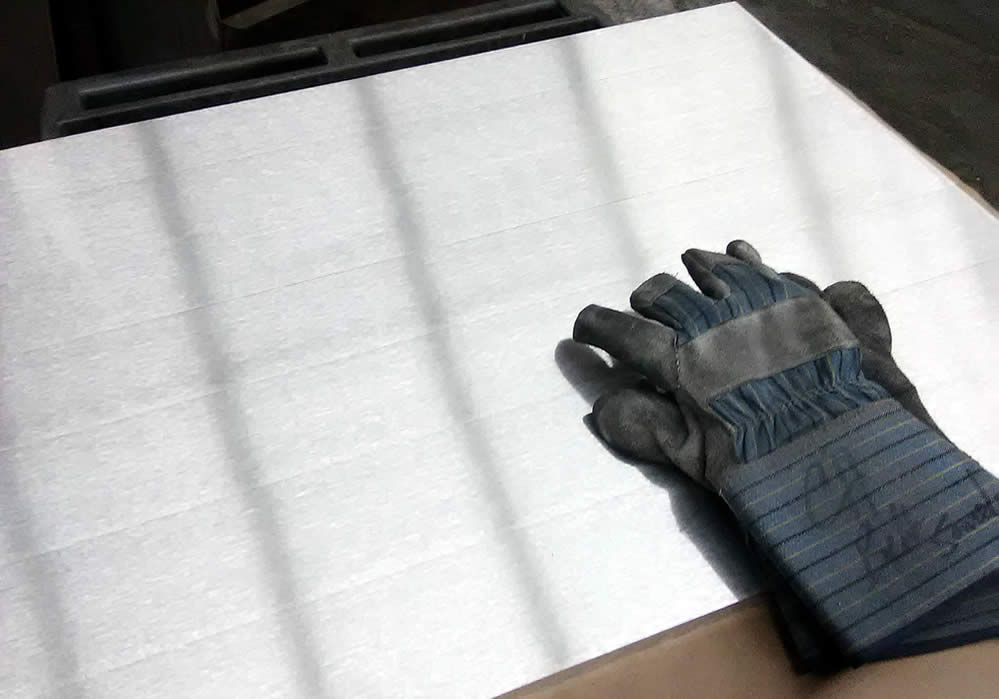

Belt sanding is a process by which flat material stampings and components are removed of all burrs and flashing.

Belt sanding can also be used to grain and/or polish flat surfaces, producing a decorative finish if required.

Micosheen utilizes Timesaver equipment, and can process material widths up to 36″ and 6″ thickness.

- Uniform Grain & Appearance

- Time & Cost Effective

- Electric Eye Tracking

- Power Height Adjustment

- Load Meter for Optimal Quality

The use of long and/or wide plates and bar stock introduces its own set of challenges, namely the uniformity of the flatness and thickness of the material. While it’s possible to process by grinding or milling to bring these within specifications – Microsheen’s wide belt machines add a new dimension to the process.

While milling may produce a satistactory result, it’s difficult to process thin sheets, accuracy is limited and the surface finish produced may still require additional processing. Grinding using stones or abrasive wheels may deliver the surface finish and accuracy, but at a much greater time expense.

Microsheen’s wide belt grinders can process materials in thicknesses ranging from 0.15 mm up to 150 mm; with and with each pass covering a width up to 36″. The result? A significant time saving plus a superior finish compared with conventional grinding.

Thanks to its straight line cutting action, fine grit belts can be used when a smooth surface is required, or coarse belts can be used when the removal of minor surface imperfections is critical.

Quality Equipment =

Quality Results